Mindoo volleyball court wood floor systems are the top of the line in making sports surfaces because they are the best wood flooring for professional volleyball courts. Our high-quality maple and oak wooden surfaces have shock absorption of at least 53%, ball bounce uniformity of at least 90%, and meet the FIBA and BWF standards for use in foreign competitions. These advanced flooring systems use a mix of old and new methods to make floors that keep players safe and improve their performance in professional places around the world.

Why Professional Volleyball Demands Superior Wood Flooring

Professional volleyball is very hard on the floors of the court, which is something that regular flooring can't handle. During kicks, blocks, and defense dives, athletes create huge contact forces. The repeated jumps create stress patterns that need special shock absorbers to handle them.

These days, volleyball is a very fast-paced sport. Players need the ball to bounce in the same way every time so they can use exact throwing methods. The surface has to give the best grip without being too rough so that you can move side to side quickly without getting hurt.

International competitions mandate strict performance standards. FIBA and BWF certifications ensure that athletic flooring meets precise technical specifications. Professional venues cannot compromise on these requirements, making quality wood flooring systems essential for serious volleyball facilities.

Our volleyball court wood floor options solve these problems with man-made wood systems that are safe, durable, and high-performing. The high-quality sports flooring keeps players and building workers safe from expensive accidents and upkeep problems.

Essential Selection Criteria for Professional Court Surfaces

Selecting superior volleyball court surfaces requires evaluating multiple technical and practical factors. My evaluation process focuses on performance metrics that directly impact player safety and game quality.

Shock absorption performance stands as the most critical factor. Professional courts require minimum 53% shock absorption to protect athletes from joint injuries. This specification reduces impact forces transmitted through players' bodies during high-intensity movements.

Ball rebound consistency affects game quality dramatically. Courts must deliver ≥90% ball rebound to ensure predictable ball behavior. Inconsistent bounce characteristics frustrate players and compromise competitive integrity.

Surface stability and deformation impact both safety and performance. Vertical deformation must remain ≤15% under standard loads. Excessive floor movement creates unstable footing and increases injury risk.

Wood species selection determines long-term durability and appearance. Maple offers superior hardness and consistent grain patterns. Oak provides exceptional durability for high-traffic applications. Birch delivers cost-effective performance for educational facilities.

Installation system design affects overall performance characteristics. Floating subfloor systems provide superior shock absorption compared to direct-stick installations. Proper ventilation prevents moisture-related problems that plague many hardwood court installations.

Certification compliance ensures international standards conformity. FIBA, BWF, and regional certifications validate performance claims through independent testing protocols.

Mindoo Premium Volleyball Court Wood Floor Systems

Our flagship volleyball court wood floor system represents the culmination of decades of sports flooring innovation. This comprehensive solution addresses every performance requirement that professional volleyball demands.

Technical Specifications Excellence:

- Total system height options: 90mm and 130mm configurations

- Premium wood species: Canadian maple, European oak, and Nordic birch

- Top surface thickness: 20mm and 22mm options

- Certified shock absorption: ≥53% (exceeds international standards)

- Ball rebound performance: ≥90% consistency rating

- Rolling load capacity: 1500N for equipment mobility

- Vertical deformation: ≤15% under standard loads

Manufacturing Excellence: Our self-owned factory maintains complete control over raw material selection and processing. We source premium hardwoods from sustainable forests, ensuring consistent quality and environmental responsibility. Advanced precision cutting and finishing techniques create perfectly consistent board dimensions.

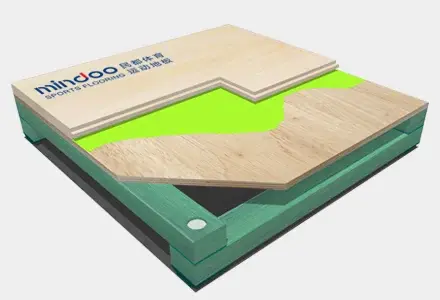

System Design Innovation: The engineered subfloor system incorporates elastic pads and structural supports that optimize shock absorption. Ventilation channels prevent moisture accumulation that damages traditional installations. The floating floor design allows natural wood movement while maintaining surface stability.

Installation Support: Our experienced installation teams provide on-site construction services worldwide. We understand that proper installation determines long-term performance. Technical support continues throughout the project lifecycle, ensuring optimal results.

Customization Capabilities: Every venue presents unique requirements. Our systems accommodate varying ceiling heights, structural limitations, and performance preferences. Custom finishing options match facility aesthetics while maintaining performance standards.

Quality Assurance: Rigorous testing protocols validate every performance claim. International certifications from FIBA and BWF confirm our systems meet professional standards. Quality control inspections occur throughout manufacturing and installation processes.

Global Market Characteristics and Regulatory Landscape

The international sports flooring market reflects diverse regional preferences and regulatory requirements. Understanding these variations helps facility operators make informed decisions about hardwood court investments.

- North American Standards: MFMA (Maple Flooring Manufacturers Association) guidelines dominate specification requirements. Emphasis on maple wood species reflects traditional preferences and proven performance. Energy efficiency considerations increasingly influence subfloor design choices.

- European Regulations: EN 14904 standards govern sports surface performance requirements across EU markets. Environmental certifications carry significant weight in procurement decisions. Multi-sport functionality requirements often influence design specifications.

- Asian Market Trends: Rapid facility construction drives demand for efficient installation systems. Cost optimization remains important, but quality standards continue rising. International tournament hosting requirements elevate specification demands.

- Emerging Market Considerations: Climate control challenges require enhanced moisture management features. Local material preferences may influence wood species selection. Training and technical support become crucial for successful installations.

Our gymnasium floor systems adapt to these varying requirements while maintaining consistent performance standards. Regional partnerships ensure local support and compliance with specific regulations. This global approach helps volleyball facilities achieve professional standards regardless of location.

Professional Installation and Maintenance Considerations

Proper floor installation and ongoing maintenance determine the long-term success of any athletic flooring investment. Our comprehensive approach ensures optimal performance throughout the system lifecycle.

- Installation Process: Site preparation begins with thorough moisture and structural assessments. Environmental controls must stabilize temperature and humidity before installation begins. Our certified installers follow precise protocols that ensure proper spacing, alignment, and fastening.

- Climate Control Requirements: Indoor volleyball court environments require consistent temperature (65-75°F) and humidity (30-50% RH) control. Seasonal variations can cause wood movement that affects performance. Proper HVAC design prevents moisture-related problems.

- Maintenance Protocols: Daily cleaning with appropriate equipment removes debris without damaging the surface. Weekly deep cleaning maintains traction characteristics. Annual inspections identify potential issues before they become costly problems.

- Refinishing Schedules: High-use facilities require refinishing every 3-5 years. Floor sanding and recoating restore surface characteristics and appearance. Our maintenance teams provide refinishing services that minimize facility downtime.

- Long-term Care: Proper maintenance extends floor life beyond 20 years. Protective coatings preserve wood appearance and performance. Regular maintenance costs significantly less than premature replacement.

Purchasing Recommendations and Investment Considerations

Investing in premium sports court design requires balancing immediate costs against long-term value. My recommendations help facility operators make informed decisions that optimize their flooring investments.

- Budget Planning: Quality volleyball court wood floor systems represent significant investments. However, the total cost of ownership often favors premium systems due to reduced maintenance and longer service life. Consider installation, maintenance, and replacement costs over 15-20 year periods.

- Specification Development: Work with experienced suppliers to develop appropriate specifications. Consider usage intensity, multi-sport requirements, and local environmental conditions. Avoid over-specifying features that provide no practical benefit.

- Supplier Selection: Choose suppliers with proven track records in sports flooring. International certifications validate technical capabilities. References from similar facilities provide insight into long-term satisfaction.

- Installation Timing: Plan installations during low-usage periods to minimize disruption. Allow adequate time for proper installation and curing. Rush installations often compromise quality and long-term performance.

- Warranty Considerations: Comprehensive warranties protect against manufacturing defects and installation problems. Understand warranty terms and maintenance requirements. Local service availability affects warranty value.

Industry Trends and Future Outlook

The sports flooring business is always changing in order to improve efficiency and make floors more environmentally friendly. New technologies make better noise reduction and ball bounce. It is getting more and more important for people who run facilities to get environmental licenses. Digital tracking tools give you real-time info on how the floor is performing. These trends make high-end wood systems, like volleyball court wood floor, a long-term choice that can change to new needs while keeping the performance benefits they are known for.

Frequently Asked Questions

Q1: How long does volleyball court wood floor installation typically take?

A: Professional installation usually requires 2-4 weeks depending on court size and complexity. Site preparation takes 3-5 days, floor installation requires 7-10 days, and finishing work needs 5-7 days including curing time. Weather conditions and facility access can affect these timelines.

Q2: What maintenance is required for hardwood volleyball courts?

A: Daily sweeping removes debris and maintains traction. Weekly damp mopping with approved cleaners preserves the surface. Annual professional inspections identify potential issues. Refinishing every 3-5 years restores performance and appearance.

Q3: Can volleyball court surfaces accommodate other sports?

A: Yes, properly designed athletic flooring supports multiple sports including basketball, badminton, and indoor soccer. Game line options allow facility flexibility. Multi-sport capability maximizes facility utilization and return on investment.

Partner with Mindoo for Premium Volleyball Court Wood Floor Solutions

Mindoo offers a wide range of sports flooring that is a great deal, exceeds international performance standards, and meets the needs of all players. We are a top volleyball court wood floor manufacturer and handle the entire process of making the floors. This includes using high-quality trees and modern techniques. Our factory always makes sure that quality and specs are right. We cut out the middleman and offer great prices without lowering quality.

With a diverse project portfolio, we serve educational institutions, professional venues, and commercial facilities. Our solutions balance performance with budget considerations, ensuring durability and aesthetic appeal. International certifications from FIBA and BWF validate our technical expertise, and rigorous testing ensures all systems meet professional standards. Our after-sales service includes maintenance programs that optimize performance and extend service life, while our technical support team is always available to assist. Ready to enhance your volleyball facility with premium hardwood flooring? Contact us at sales@mindoofloor.com to discuss your project's specifications and requirements.

References

- International Volleyball Federation. "FIBA Approved Suppliers and Licensed Products Manual." Technical Commission Guidelines for Competition Venues, 2023.

- Maple Flooring Manufacturers Association. "Sports Floor Specification and Installation Guidelines." Professional Standards for Athletic Hardwood Surfaces, 2023.

- European Committee for Standardization. "EN 14904:2006 Surfaces for Sports Areas - Indoor Surfaces for Multi-Sports Use." Performance Requirements and Test Methods.

- American Sports Builders Association. "Guidelines for Multi-Purpose Athletic Floor Systems." Design and Installation Best Practices, 2023.

- Journal of Sports Engineering and Technology. "Impact Absorption Characteristics of Athletic Floor Systems." Performance Analysis of Professional Court Surfaces, Vol. 235, 2023.

- International Association of Gymnasium Flooring Contractors. "Global Standards for Sports Flooring Installation and Maintenance." Technical Reference Manual, 2023.