It is necessary to adhere to stringent quality requirements and meticulously plan the installation of hardwood flooring for sports facilities. In especially for specialist applications such as Badminton Court Wooden Flooring, pre-installation checks, which serve as the basis for successful flooring projects, are essential. In addition to eliminating expensive installation failures that may interrupt facility operations and put player safety at risk, these essential measures guarantee outstanding performance, compliance with safety regulations, and long-term durability.

Understanding the Scope: Why Pre-Installation Checks Matter

The pre-installation verification that is carried out has a direct influence on the lifespan of sports flooring systems as well as the performance specifications of such systems. If facility managers fail to take into account these essential processes, it is probable that they could encounter significant structural issues, such as warping, moisture damage, and uneven surfaces. These issues might be caused by significant structural difficulties. There is a possibility that these issues will have a significant impact on the requirements for safety and athletic performance.

Impact on Performance and Safety Standards

It is possible to ensure that wooden sports flooring will meet the requirements for international certification, such as those established by FIBA and BWF, provided the pre-installation assessment is carried out in the appropriate manner. A sufficient amount of shock absorption and high ball rebound rates are two of the performance metrics that are defined by these recommendations. In the event that you do not do all of the necessary testing, you run the risk of having flooring that breaks prematurely, which would lead to costly repairs and possibly worries about responsibility.

Compliance with International Sports Standards

Sports facilities in the modern era are required to comply with tight regulatory criteria that control everything from the limits of vertical deformation to the surface friction restrictions. For the purpose of preserving certification status and ensuring that insurance coverage is maintained, installations of a professional grade need comprehensive documentation of the subfloor conditions, environmental controls, and material specifications.

Key Technical Checkpoints Before Installing Wooden Flooring

The success of projects involving the installation of hardwood flooring is determined by a number of essential elements, and technical preparation incorporates all of these aspects. When it comes to the installation of professional sports flooring, such as Badminton Court Wooden Flooring, the most important aspects are the selection of materials, conducting an environmental assessment, and evaluating the structure.

Material Selection and Wood Species Evaluation

There is a substantial impact on both performance and durability when the appropriate species of wood is chosen. Maple, oak, birch, and beech are all examples of premium hardwoods that provide a variety of advantages when it comes to use in sports. Oak offers exceptional durability for high-traffic areas, while maple also provides good shock absorption and grain patterns that are uniform throughout. Throughout the lifetime of the floor, professional installers often make use of surface thicknesses that guarantee adequate resistance and the ability to be refinished.

Subfloor Assessment and Preparation

At the end of the installation process, the conditions of the subfloor are an extremely important factor. The testing of the moisture content, the verification of the levelness, and the assessment of the structural integrity are all components of a comprehensive examination. While concrete substrates should be kept in a dry state, the acceptable moisture levels for timber subflooring fall within a moderate range. For the purpose of avoiding performance problems and premature wear patterns, deviation tolerances for levelness should be kept to a minimum.

Environmental Control Systems

Climate control systems are required to be operational and calibrated prior to the beginning of the installation process. A temperature range that is moderate and relative humidity that is kept at a level that is pleasant comprise the ideal environmental conditions. Both expansion and contraction problems, which might affect the integrity of the installation, are avoided by these measures, which guarantee that the wood is properly acclimated.

Cost, Procurement, and Supplier Considerations

Procurement techniques that are effective strike a balance between the initial investment costs, the long-term performance needs, and cost of maintenance. Facility managers are able to make more educated choices that are in line with operational budgets and performance goals when they have a thorough understanding of the total cost of ownership.

Budget Planning and Cost Analysis

Comprehensive budget planning goes beyond material costs to include installation labor, site preparation, and ongoing maintenance needs. Professional installations with varying heights, depending on the sleeper layers, require specialized expertise and equipment, impacting both project timelines and costs. Quality installations typically account for a significant portion of the total budget, highlighting the importance of choosing experienced contractors.

Supplier Evaluation and Certification Verification

Evaluation of manufacturing capabilities, compliance with certification requirements, and expertise in project management are all criteria that must be considered when selecting eligible suppliers. Rolling load ratings, vertical deformation limits, and shock absorption performance data are some of the technical parameters that are provided by reputable suppliers. These suppliers also regularly maintain extensive quality assurance procedures. Validation of product quality and assurance of conformity with sports facility criteria are both accomplished via the acquisition of international certifications from recognized agencies.

Maintenance, Lifespan, and Long-Term Performance Optimization

Long-term performance optimization requires the deployment of proactive maintenance procedures and regularly scheduled performance monitoring in order to safeguard investment value and maintain safety standards throughout the working lifespan of the flooring system, especially for Badminton Court Wooden Flooring. This is necessary on a regular basis.

Preventive Maintenance Protocols

Effective maintenance programs include daily cleaning procedures, periodic moisture monitoring, and scheduled refinishing intervals. Professional-grade wooden sports floors typically require refinishing every several years, depending on usage intensity and environmental conditions. Regular maintenance extends operational lifespan while preserving performance characteristics essential for competitive play.

Performance Monitoring and Quality Assurance

Annual evaluations of shock absorption, ball bounce characteristics, and surface integrity are all part of the ongoing performance monitoring process. The purpose of these reviews is to verify that sports facilities continue to comply with the standards that have been established and to detect possible problems before they put player safety or facility operations at risk. In order to facilitate the procedures of facility certification renewal and warranty claims, documentation of performance indicators is essential.

Summary and Final Recommendations

Successful wooden flooring installation depends on comprehensive pre-installation planning that addresses technical requirements, environmental conditions, and long-term maintenance considerations. The following checklist consolidates essential verification steps: subfloor moisture content testing, levelness verification, environmental system calibration, material acclimation confirmation, and supplier certification validation. Facility managers who implement these protocols significantly reduce installation risks while ensuring optimal performance outcomes. Strategic partnerships with experienced suppliers and installation teams provide additional assurance and support throughout the project lifecycle, especially for Badminton Court Wooden Flooring installations.

Conclusion

Thorough testing before placement is the key to a good wooden sports flooring project. If facility managers put an emphasis on thorough assessment processes, choosing high-quality materials, and working with experienced suppliers, they can get better installation results while keeping long-term running costs low. The money spent on proper planning is returned in the form of better performance, longer life, and continued certification compliance. Badminton Court Wooden Flooring projects provide the best value over their entire working lifetime when they are planned strategically to include technical needs, environmental controls, and upkeep issues.

Frequently Asked Questions

Q1: What wood species provides the best performance for badminton court applications?

A: Maple stands out as the preferred choice for badminton courts due to its exceptional shock absorption properties, consistent grain structure, and proven durability under intensive use. Oak and birch also perform well, with each species offering specific advantages depending on facility requirements and budget considerations.

Q2: How thick should wooden flooring be for optimal badminton court performance?

A: Professional badminton courts typically utilize surface thickness ranging from 20mm to 22mm. This specification provides adequate shock absorption while allowing for multiple refinishing cycles throughout the floor's operational lifespan, ensuring consistent performance and long-term value.

Q3: What certification standards should wooden sports floors meet for competitive play?

A: Quality sports floors must comply with BWF (Badminton World Federation) and FIBA standards, which specify performance criteria such as adequate shock absorption, high ball rebound rates, and limited vertical deformation. These certifications ensure player safety and provide optimal playing conditions.

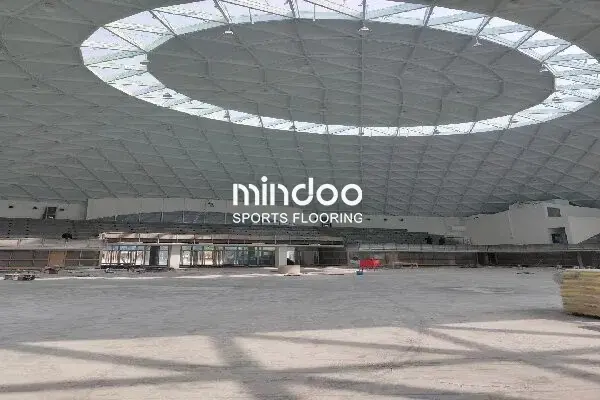

Partner with Mindoo for Premium Sports Flooring Solutions

Mindoo delivers comprehensive wooden sports flooring solutions backed by international certifications and proven manufacturing excellence. Our self-owned factory ensures quality control throughout production while maintaining competitive pricing for commercial and institutional clients. We specialize in customizable installations featuring premium wood species including maple, oak, birch, and beech with performance specifications that exceed industry standards. Our integrated approach covers design consultation, manufacturing, installation, and ongoing maintenance support. As a trusted Badminton Court Wooden Flooring manufacturer, we provide turnkey solutions that meet BWF and FIBA certification requirements. Contact us at sales@mindoofloor.com to discuss your project requirements and discover competitive advantages that ensure successful installation outcomes.

References

- International Association of Gymnastics Federations. "Sports Floor Performance Standards and Testing Protocols." Technical Manual for Wooden Sports Surfaces, 2023.

- Badminton World Federation. "Court Surface Requirements and Certification Guidelines." BWF Technical Regulations, 2024.

- American Sports Builders Association. "Best Practices for Wooden Sports Floor Installation." Professional Installation Guidelines, 2023.

- Wood Flooring International. "Moisture Control and Environmental Management in Sports Facilities." Technical Research Publication, 2023.

- Sports Facility Management Association. "Pre-Installation Assessment Protocols for Wooden Athletic Surfaces." Industry Standards Manual, 2024.

- International Basketball Federation. "Wooden Floor Installation and Maintenance Standards." FIBA Technical Handbook, 2023.