Are you looking for OEM beech sports flooring that fits your brand perfectly? Businesses can make unique hardwood flooring experiences that stand out in today's competitive market with custom sports flooring solutions. Professional beech sports flooring is very durable, absorbs shocks very well, and can be changed to fit the needs of sports facilities all over the world. OEM partnerships give you the freedom to design exactly what your customers want, whether you're making athletic performance surfaces for basketball courts or custom sports flooring for venues that can be used for more than one thing.

Understanding the Differences Between OEM and ODM Quality in Making Sports Flooring

Partnerships between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) have changed the way businesses look at custom sports flooring solutions. Brand owners and distributors can use each other's manufacturing knowledge while still keeping full control over the identity of their products thanks to these partnerships.

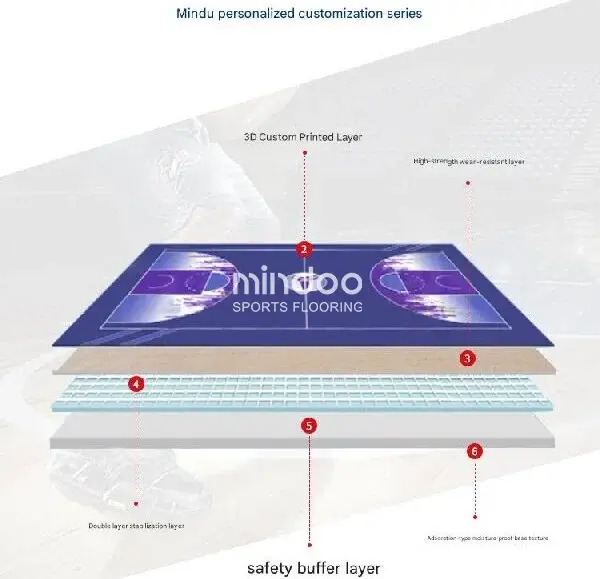

Surfaces that are precisely engineered and meet strict international standards are needed in the sports facility industry. Our dedication to quality is shown by our beech sports flooring, which has FIBA and BWF certifications that prove its performance in a number of different sports. With total heights of 90mm and 130mm, these systems can meet a wide range of athletic needs while still meeting high quality standards.

Installing a modern sports court requires more than just basic functionality. They need surfaces that improve athletic performance and show what the brand stands for. Businesses can change every part of their flooring systems through OEM partnerships, from the surface texture to branding elements. This gives them a unique advantage in markets that are very competitive.

Mindoo's integrated approach to making sports flooring includes finding the best raw materials, processing them precisely, and checking the quality of the finished product thoroughly. This kind of vertical integration makes sure that the quality of the products stays the same and lets them be customized quickly in a way that traditional suppliers can't.

Mindoo's Full Range of OEM Manufacturing Skills

Our own factory gives us a big edge over our competitors in the market for custom sports flooring. We can make changes quickly and keep strict quality standards throughout all manufacturing cycles because we have direct control over the whole production process.

The technical details of our beech sports flooring show that we are dedicated to providing the best performance possible. With shock absorption rates above 53% and vertical deformation rates below 15%, these surfaces keep athletes safe and provide consistent ball rebound characteristics above 90%. A rolling load capacity of 1500N makes sure that it will last for a long time even under heavy use.

Our understanding of different customer needs has grown as we've worked on a wide range of construction projects. The needs for athletic performance are very different between basketball courts and volleyball courts. Our engineering team changes the way systems are set up to get the best performance for different sports while keeping the quality of the manufacturing process high.

International certifications show that we are serious about meeting quality standards around the world. Customers can be sure that the product is reliable because of these credentials, and it's easier for contractors and architects to make specifications. Protocols for quality assurance include thorough testing at every stage of production, which makes sure that performance is the same from one production run to the next.

When you're in charge of big projects, supply chain reliability is very important. Our approach to integrated manufacturing means we don't have to rely on outside suppliers for important parts. This cuts down on lead times and makes sure that materials are always available for custom orders.

Full customization options to set your brand apart

Customizing a physical design goes far beyond changing the finishes on the outside. Our beech sports flooring can have top surfaces that are between 22 mm and 30 mm thick, so it can be optimized for different performance needs. With widths ranging from 60mm to 80mm, you can make your installation even more flexible.

Functional features can be changed to make certain sports better. Different levels of shock absorption, anti-slip surface treatments, and moisture resistance can be changed depending on how the product will be used. These changes make sure that the best performance is maintained while still meeting safety standards.

Custom logos, color schemes, and surface patterns are all ways that brands can be integrated into sports facilities to make them more recognizable. Customers who care about the environment will like eco-friendly materials and sustainable manufacturing processes, and these will also help with corporate responsibility efforts.

Different global markets have very different compliance requirements. Because we are familiar with international standards, we can change our products to meet the needs of different regions while keeping their main performance traits. This flexibility makes it easier for distributors and brand owners to get into new markets.

Customizing the packaging makes the brand more visible throughout the whole customer experience. Custom designs for packaging, installation guides, and maintenance instructions help businesses look more professional while also being useful to end users.

Strategic ODM partnerships to lead in innovation

Through ODM relationships, companies can work together to create the next generation of sports flooring solutions that are ahead of the curve in terms of market trends. Through these partnerships, we're able to combine our manufacturing knowledge with information about the customer market to make new products that give us a competitive edge.

The first step in the co-development process is to do a full analysis of the market and define the performance requirements. Our engineering team works closely with partners to find ways to make existing designs better and to come up with new features that make the user experience better.

With prototype development, new ideas can be tested quickly before they are put into full-scale production. This iterative method lowers the risks of development and makes sure that the final products perform as expected. Protocols for testing make sure that shock absorption, durability, and athletic performance are valid in real-world settings.

Advanced surface treatments, better installation systems, and better maintenance protocols are all examples of ways that technology can be used together. These new features make products stand out in crowded markets and give real benefits to customers.

Market exclusivity agreements protect partner investments in product development and make sure that investments in innovation get a good return. These arrangements make sure that everyone is safe and encourage everyone to work together on future projects.

Streamlined management of the customization process

The first step in our customization process is in-depth consultations where we find out exactly what you need and what your performance goals are. Technical requirements, personal tastes in style, and financial limits are all set during these initial talks.

A thorough engineering analysis is part of the design development process to make sure that all modifications don't affect the structure's strength or performance. Before production starts, computer modeling makes sure that design ideas are sound and finds any problems that might come up during production.

Sample production lets customers see how real prototypes work before they place large orders. These samples go through the same quality control steps as full production runs. This makes sure that the characteristics of the final product are accurately shown.

The scheduling of production meets the needs of customers for meeting deadlines while maintaining quality standards. Customers are kept up to date on progress on a regular basis during manufacturing cycles. This makes it easier to coordinate with other project activities.

As part of quality assurance, finished products are tested thoroughly against established standards. Documentation packages include detailed information about performance that helps with planning installations and keeping up with maintenance.

Unique Value Proposition for Business Growth

Our approach to integrated manufacturing, which gets rid of markups in the middle and keeps quality standards high, saves you money. Direct factory pricing lets you position yourself in a competitive market without lowering your profit margins.

Simplifying the design and production processes speeds up the time it takes to get a product to market. Rapid prototyping lets you respond quickly to market opportunities, and a wide range of manufacturing resources makes sure that delivery dates are met every time.

Technical support goes beyond the initial delivery and includes help with installation and ongoing advice on maintenance. Our experienced team gives useful advice that makes sure products work at their best throughout their entire lives.

Unique customization options that standard suppliers can't match give you a chance to stand out from the competition. Custom features and improvements to performance make products stand out and justify higher prices.

Long-term benefits of a partnership include first-choice production schedules, exclusive design rights, and ongoing support for new ideas. These connections make business planning more stable and make sure that companies can use the newest technologies.

Conclusion

Custom beech sports flooring is more than just a surface; it shows how committed your brand is to quality and performance. Mindoo offers a wide range of OEM services that help companies make unique products that meet strict requirements and meet international quality standards. Our approach to integrated manufacturing guarantees on-time delivery, low prices, and ongoing technical support that leads to long-term success. Because Mindoo is reliable, has advanced engineering, and can be customized in many ways, it is the best company to work with on your next sports flooring project.

Frequently Asked Questions

Q1: What customization options are available for beech sports flooring systems?

A: We offer comprehensive customization including thickness variations (22mm-30mm), width options (60mm-80mm), custom surface treatments, branding integration, and performance modifications for specific sports applications. All customizations maintain international certification standards.

Q2: How long does the custom beech sports flooring development process typically take?

A: Development timelines vary based on complexity, but typical projects require 2-3 weeks for design validation, 1-2 weeks for sample production, and 3-4 weeks for full production runs. Rush orders can be accommodated with adjusted scheduling.

Q3: What quality assurances do you provide for custom sports flooring orders?

A: All custom products undergo identical quality control processes as standard offerings, including shock absorption testing, durability validation, and performance verification. International certifications (FIBA, BWF) apply to custom configurations that meet specification requirements.

Partner with Mindoo for Premium Custom Sports Flooring Solutions

Ready to develop your custom beech sports flooring line that outperforms competitors? Mindoo's proven OEM capabilities and comprehensive manufacturing resources provide everything needed to create distinctive hardwood flooring solutions. Our experienced team understands the unique challenges of sports facility projects and delivers reliable results that exceed expectations.

Whether you're a distributor seeking a dependable beech sports flooring supplier or a brand owner developing new product lines, our flexible manufacturing approach accommodates diverse requirements while maintaining consistent quality standards. Professional sports floor installations demand precision engineering and reliable performance - qualities that define every Mindoo product.

Don't settle for standard solutions when custom options can differentiate your brand in competitive markets. Contact our team today to discuss your specific requirements and discover how our OEM partnership can accelerate your business growth. Reach out to contact us at sales@mindoofloor.com to begin developing your custom sports flooring solution.

References

- International Basketball Federation (FIBA). "Technical Requirements for Basketball Court Surfaces." FIBA Equipment and Venue Manual, 2023 Edition.

- Badminton World Federation (BWF). "BWF Approved Court Surface Standards for Professional Competition." BWF Technical Regulations, 2023.

- American Sports Builders Association. "Sports Flooring Performance Standards and Testing Protocols." ASBA Technical Guidelines, 2023.

- European Committee for Standardization. "EN 14904:2022 - Surfaces for Sports Areas - Indoor Surfaces for Multi-Sports Use - Specification." CEN Standards Publication.

- International Association of Athletics Federations. "Track and Field Facilities Manual: Surface Performance Requirements." World Athletics Technical Manual, 2023.

- Forest Stewardship Council. "Sustainable Hardwood Sourcing Standards for Sports Flooring Applications." FSC Certification Guidelines, 2023.