The Role of Rolling Load Resistance in Sports Hardwood Floors

When it comes to sports flooring, particularly hardwood surfaces, one of the most critical aspects often overlooked is the floor’s resistance to rolling loads. This performance characteristic plays a significant role in the overall durability, safety, and functionality of the floor, especially in high-traffic, multi-purpose environments like gyms, sports halls, and arenas. The term "rolling load" typically refers to the pressure applied by equipment such as basketball carts, wheelchairs, bleachers, or even heavy machinery used during setup or maintenance. This article delves into the importance of rolling load resistance in sports hardwood floors, exploring how it affects the floor’s longevity, performance, and the overall experience of athletes and facility managers alike.

1. What is Rolling Load Resistance?

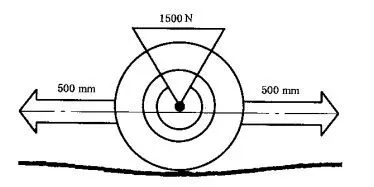

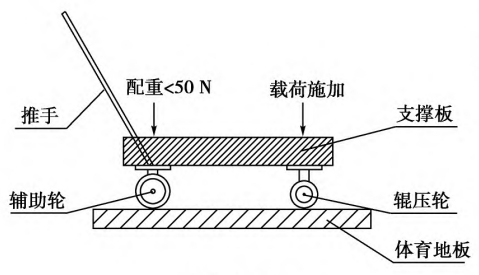

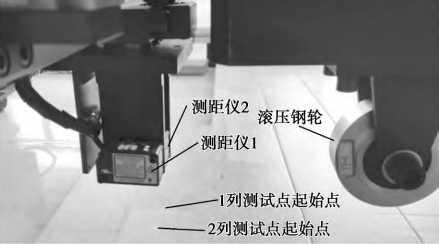

Rolling load resistance refers to a floor’s ability to maintain its structural integrity under the stress of objects that move across it while exerting pressure. In the context of sports hardwood floors, this typically involves wheeled equipment that may repeatedly roll over the surface. These loads don’t just impact the top surface; they also affect the subfloor and underlying layers that support the wood panels. For a floor to be functional in sports settings, it must not only support the weight but also prevent significant wear or deformation over time.

The resistance to rolling loads can be measured by observing how much a floor deforms under repeated pressure, as well as its ability to recover and maintain an even surface. Floors with inadequate rolling load resistance may experience indentations, warping, or even cracking, particularly in areas with consistent movement, such as around courtside benches or locker room areas.

2. Why is Rolling Load Resistance Crucial for Sports Floors?

The ability of a sports floor to resist rolling loads has several important implications for both the maintenance and the performance of the facility.

Preserving the Surface Integrity: Constant rolling of heavy equipment like chairs, tables, and carts can cause localized damage if the floor is not designed to withstand it. This damage could range from surface dents to deeper gouges, potentially leading to costly repairs or replacement. Floors that can resist rolling loads are more resilient, maintaining their visual appeal and functional quality over a longer period.

Safety and Performance: A floor that has become deformed due to rolling load damage can create hazards for athletes. Uneven surfaces can increase the risk of slips, trips, and falls. Moreover, the performance of the sport itself can be compromised if the floor’s bounce or grip is negatively affected. Proper resistance to rolling loads ensures that the floor remains level and consistent, providing a safe environment for athletes to perform at their best.

Maintenance and Longevity: Floors that are resistant to rolling loads require less frequent maintenance, which translates to significant cost savings over time. The ability to withstand rolling loads without warping or indenting means that the surface will not need to be resurfaced or repaired as often. This leads to a longer lifespan for the flooring and reduces the frequency of downtime needed for repairs.

3. How Does Rolling Load Resistance Affect Floor Design?

Sports hardwood floors are engineered to provide optimal performance across a variety of activities, and rolling load resistance is one of the key factors that influence their design. Here are several ways that rolling load resistance is incorporated into the design of sports flooring systems:

Subfloor and Structural Support: To effectively resist rolling loads, the floor system often includes a robust subfloor structure. This layer is designed to distribute the pressure exerted by rolling equipment evenly, preventing concentrated stress points that could lead to damage. The subfloor material and construction are as important as the hardwood surface in ensuring overall performance.

Wood Species Selection: Different wood species have varying degrees of strength and durability, which directly impacts their rolling load resistance. Hardwoods like maple, which are commonly used in sports flooring, have excellent resistance to rolling loads due to their density and structure. Lighter woods may not offer the same level of protection and could be more susceptible to damage under heavy rolling loads.

Finish and Coating: The finish applied to the hardwood also plays a role in its ability to resist damage from rolling loads. High-quality finishes not only enhance the wood’s appearance but also provide an additional layer of protection against wear and tear. Polyurethane finishes, for example, are commonly used to enhance the durability of sports floors, offering protection from both rolling loads and daily foot traffic.

Design Flexibility: When designing a sports floor to resist rolling loads, manufacturers can also optimize the floor for multi-purpose use. In many gyms and sports arenas, floors are exposed to not just athletes, but also the rolling of chairs, carts, and other heavy equipment. This dual-use capability requires a balanced approach to design, ensuring that the floor can handle both dynamic sports action and the static pressure of rolling loads.

4. Practical Considerations for Facility Managers

For facility managers, understanding rolling load resistance is essential in selecting and maintaining sports hardwood flooring. When choosing a floor system, here are a few key considerations:

Assess Equipment Types: The type of equipment that will frequently roll over the floor should be taken into account. For example, basketball arenas often deal with large wheeled carts for storing basketballs and other supplies, while multipurpose gyms may have more varied types of rolling equipment, including chairs and fitness machines. The floor needs to be tailored to withstand these specific pressures.

Evaluate Floor Performance Over Time: Rolling load resistance can degrade over time, especially in areas that experience the most traffic. Managers should monitor the performance of the floor in high-traffic zones and consider periodic assessments to identify any early signs of damage or deformation. Regular maintenance and refinishing can extend the life of the floor and ensure it continues to perform well under rolling loads.

Choosing the Right Flooring System: Not all sports hardwood flooring systems are created equal when it comes to rolling load resistance. Systems that combine a high-quality hardwood layer with a durable subfloor and robust moisture control measures tend to perform best in environments where rolling loads are a concern. Managers should consider investing in these advanced systems to reduce long-term maintenance costs and avoid downtime.

From preserving the floor’s surface integrity to reducing maintenance costs and improving athlete safety, investing in high-quality flooring that is designed to withstand rolling loads is a wise decision for any sports venue. Facility managers should prioritize this feature when selecting new floors and stay vigilant about maintenance to ensure the floor continues to perform at its best.