What is PVC Badminton Court Flooring and How Does it Work?

For indoor racket sports, badminton court pvc flooring is a modern plastic surface option. Mixing polyvinyl chloride materials with special backing layers makes this new flooring system perfect for playing. Multi-layer design gives you better grip, controlled ball spin, and shock reduction. International badminton league standards for professional and pleasure sites are met by interlocking installation methods for badminton court pvc flooring. These make smooth playing areas.

What is Badminton Court PVC Flooring?

PVC sports flooring for badminton, specifically badminton court pvc flooring, offers a high-performance surface with multiple layers designed for safety and optimal play. The foundation features dense foam or rubber backing for cushioning, while the core PVC layer ensures structural integrity. The textured top layer provides ideal traction without excessive grip, reducing injury risks.

Advanced PVC materials are used with additives like UV stabilizers, anti-bacterial agents, and flexibility enhancers to improve durability and maintain performance across varying temperatures.

The manufacturing process involves precise calendering for uniform thickness and consistent ball bounce. Installation options range from modular tiles for temporary courts to permanent, bonded solutions for professional venues.

Core Problems PVC Flooring Solves for Sports Facilities

Traditional materials for badminton court floors don't always meet the high standards of current sports centers. Extreme joint stress and poor shock absorption on concrete surfaces make players tired and increase the chance of accidents. Although wooden courts work well, they need a lot of upkeep and can be damaged by water and bending.

PVC flooring solves these problems with specially designed products that put player safety and building operations first. Compared to harder surfaces, the flooring's shock-absorbing qualities make it much easier on players' knees when they hit something. This cuts down on the chance of abuse injuries by a lot, especially knee and joint problems that happen a lot in badminton.

Another important benefit for building managers is that badminton court PVC flooring doesn't absorb moisture. Not like wooden surfaces that can bend or break when the humidity changes, PVC stays the same size even when the environment changes. This steadiness gets rid of the need for expensive fixes and downtime that come with using traditional materials.

The non-slip sports flooring characteristics of quality PVC surfaces provide consistent traction that adapts to different playing styles and movements. The surface texture creates optimal grip for quick lateral movements while allowing controlled sliding when needed for extended reaches.

Maintenance simplification transforms facility operations dramatically. Traditional wooden courts require daily dust mopping, periodic refinishing, and careful humidity control. PVC surfaces need only regular cleaning with standard equipment and occasional deep cleaning, reducing labor costs and maintenance complexity.

Sound absorption properties built into modern PVC systems reduce noise levels significantly compared to hard surfaces. This acoustic control creates more comfortable environments for both players and spectators while meeting noise regulations for multi-use facilities.

Advanced Technology Behind PVC Court Performance

The engineering sophistication of modern badminton court flooring material involves multiple technological innovations working in harmony. The cellular structure of the backing foam utilizes closed-cell design that prevents moisture absorption while maintaining consistent compression characteristics over time.

Surface texturing technology creates microscopic patterns that optimize friction coefficients for badminton-specific movements. These patterns undergo extensive testing using standardized sliding resistance measurements to ensure they fall within the optimal range for player safety and performance.

Thermal stability is a key technical advancement in PVC formulation. Sports facilities often experience significant temperature fluctuations, and inferior materials can become too soft in warm conditions or brittle in cold ones. Advanced PVC compounds maintain consistent flexibility and performance across a wide range of temperatures.

The interlocking mechanism for modular systems utilizes precision-molded edges that create seamless joints. These joints distribute loads evenly across the surface, preventing edge lifting or separation under intensive use. The connection system allows for natural thermal expansion while maintaining surface integrity.

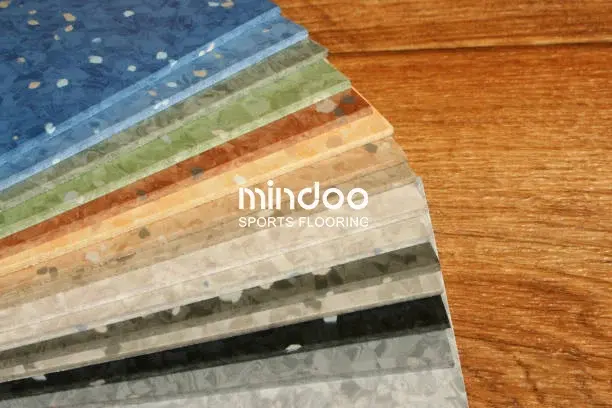

Color integration technology embeds pigments throughout the wear layer rather than applying surface coatings. This through-color construction ensures consistent appearance even after years of use and prevents color loss from scratching or wear patterns.

Anti-static properties built into the PVC formulation prevent dust accumulation and reduce cleaning requirements. The controlled electrical conductivity also enhances player comfort by eliminating static buildup during play.

Installation Methods and Technical Specifications

Professional badminton court installation demands careful attention to substrate preparation and environmental conditions. The foundation must be level within a small tolerance over a reasonable distance and completely dry before installation begins. Concrete substrates require adequate curing time and moisture testing to avoid potential adhesion issues in the future.

Adhesive selection depends on the specific PVC product and environmental conditions. Pressure-sensitive adhesives facilitate easier future removal and replacement, while permanent adhesives provide stronger bonds for high-traffic installations. The adhesive application rate generally covers a moderate area per gallon, applied with notched trowels to ensure even and uniform coverage.

Acclimation procedures require PVC materials to reach room temperature before installation. This process usually takes a day or two and helps prevent expansion or contraction issues after the court is finished. Rolls should be unrolled and left to relax, allowing any memory curl from shipping and storage to disappear.

Seaming techniques for larger courts involve precise cutting and joining procedures. Heat welding creates the strongest seams for professional installations, while tape seaming offers adequate performance for recreational facilities. Proper seaming eliminates trip hazards and prevents moisture infiltration.

Quality control measures include surface testing for hardness, slip resistance, and ball bounce characteristics. Professional installations undergo comprehensive inspection using standardized testing equipment to verify compliance with international sports flooring standards.

Post-installation procedures include initial cleaning to remove any installation residues and applying a protective film if required. The surface generally needs a curing period of a day or two before initial use to allow the adhesives to reach their full strength.

Key Advantages for Different Market Segments

Contractors and architects value PVC flooring for its predictable installation and reliable performance. Clear documentation and guidelines minimize risks, ensuring smooth project execution and successful results.

Sports facility operators benefit from PVC's durability, low maintenance, and easy cleaning. Its shock absorption and ball bounce meet league standards, while reducing custodial labor and maintaining appearance.

Commercial developers value PVC sports surfaces for their aesthetic flexibility, durability, and long-term value. The material resists wear and stains, reducing replacement costs while meeting performance and design needs.

Specialized distributors appreciate PVC manufacturers for reliable supply, competitive pricing, and predictable demand. Shelf stability aids inventory, while technical support and marketing materials boost customer service and sales growth.

High-quality PVC systems for badminton courts last a long time and offer a great return on investment across many market groups. Tests done by outside groups have shown that these systems can last for many years with normal use, much longer than many standard options.

Potential Limitations and Important Considerations

Even though PVC flooring has many benefits, building builders should be aware of some issues and limits. Initial material costs are usually higher than basic options like painted concrete. However, lifetime analysis usually favors PVC systems because they need less upkeep.

Temperature sensitivity can affect some PVC formulations, especially in unregulated environments, with heat causing softening and cold reducing flexibility. Quality products provide specific temperature ranges for consistent performance.

Installation requires skilled contractors to avoid issues like premature failure. Chemical compatibility is crucial—harsh cleaners can damage PVC, so staff must follow manufacturer guidelines. Modular systems allow for easier repairs, while bonded installations may require more extensive work. Understanding these factors aids in making the right product choice.

PVC Flooring Versus Traditional Alternatives

In badminton courts, wooden sports flooring has long been preferred for its performance and looks. However, PVC systems now match or beat these qualities while also being easier to maintain and better for the environment. Long-term, PVC flooring is cheaper than wood because it doesn't need to be refinished as often and doesn't need to be kept dry as much.

PVC systems also meet or beat international standards for shock absorption, ball bounce, and surface friction. They work the same way no matter the temperature or humidity. PVC is also better for the environment because it can be recycled and uses fewer resources, which makes it a good choice for modern sports venues.

Ideal Applications and Target Markets

PVC badminton courts with badminton court pvc flooring are great for schools because they are affordable, don't need much upkeep, and can handle a lot of use in classes and tournaments. They're also good for community leisure centers because they make sturdy, nice grounds for many activities.

Professional training centers depend on PVC systems to keep things running smoothly, keep the ball from bouncing too far, and keep people from getting hurt. Fitness centers for businesses look nice, don't need much upkeep, and run quietly. Tournament sites can be set up quickly and reliably, whether they are only there for a short time or for good.

PVC badminton court technology is advancing towards greater sustainability and performance. Bio-based formulations reduce environmental impact while retaining high performance, addressing eco-concerns without compromising on quality. Innovations in smart flooring, like embedded sensors, enable predictive maintenance, optimizing operations and prolonging court life, making badminton court pvc flooring a more sustainable and efficient choice for modern sports facilities.

Manufacturing improvements focus on integrating more recycled content and adhering to circular economy principles. Future PVC systems will incorporate higher percentages of post-consumer recycled materials, maintaining or improving performance standards. As badminton grows globally, flooring systems must adapt to diverse facility needs, supporting both recreational and competitive play while maintaining consistent performance.

Frequently Asked Questions

Q1: How long does PVC badminton court flooring typically last?

A: When used normally, good quality PVC badminton court flooring systems usually last a long time. How long it actually lasts varies on things like how often it is used, how well it is maintained, and the elements of the surroundings. Professional buildings that get a lot of use every day may not last as long, but leisure buildings usually last longer. Maintaining and cleaning the flooring properly on a regular basis can make it last a lot longer.

Q2: Can PVC badminton courts be installed over existing surfaces?

A: Yes, PVC systems can often be put down on top of old floors that meet certain conditions. It's important that the base is physically sound, flat, and fully dry. Substrates can be concrete, terrazzo, or even some types of wood that are already there. But a professional review is needed to find out if the two are compatible and if any planning work needs to be done.

Q3: What maintenance is required for PVC badminton court flooring?

A: PVC badminton courts are easier to keep up than standard floors. A light cleaning to get rid of dirt is part of daily maintenance. Wet cleaning the surface once a week with light, pH-neutral cleaners helps keep it looking good and keeping it clean. Deep cleaning once in a while gets rid of deep-down dirt and keeps the surface from slipping. To protect the surface's structure, don't use strong chemicals, too much water, or rough methods.

Partner with Mindoo for Superior Badminton Court Solutions

Mindoo stands ready to support your badminton court renovation or new construction project with industry-leading expertise and premium flooring solutions. As an experienced badminton court pvc flooring manufacturer, we understand the unique requirements of sports facilities and deliver tailored solutions that exceed performance expectations. Our self-owned factory ensures competitive pricing and reliable quality control throughout the production process. Contact us at sales@mindoofloor.com to discuss your specific requirements and discover how our certified flooring systems can enhance your facility.

References

- International Badminton Federation. "Technical Specifications for Badminton Court Surfaces and Performance Standards." BWF Equipment Approval Manual, 2023 Edition.

- Sports Flooring Institute. "Comparative Analysis of Synthetic Sports Flooring Materials: Performance, Durability, and Lifecycle Costs." Journal of Sports Facility Management, Vol. 34, 2023.

- American Society for Testing and Materials. "Standard Test Methods for Sports Flooring Systems: Shock Absorption, Ball Bounce, and Surface Friction." ASTM F2772-21 Standards Manual.

- Zhang, Li Wei and Johnson, Michael R. "Advanced PVC Formulations for Indoor Sports Applications: Materials Science and Performance Engineering." International Conference on Sports Surface Technology Proceedings, 2023.

- European Committee for Standardization. "Sports Floors - Point Elastic Sports Floors - Specification and Test Methods for PVC Systems." EN 14904:2022 Technical Standard.

- National Federation of State High School Associations. "Facility Standards and Guidelines for Indoor Court Sports: Safety, Performance, and Maintenance Requirements." NFHS Facility Manual, 2023 Revision.