How to Choose Fake Grass for Football: A 2026 Buyer's Guide

To choose the right football fake grass, you need to think carefully about safety standards, performance standards, and long-term value. Today's synthetic turf technology gives cities, sports clubs, contractors, and site managers better options than real grass. Fiber quality, filling systems, draining abilities, and upkeep needs are some of the most important factors. When compared to natural grass grounds, professional-grade fake turf is more constant in how it can be used and has less of an effect on the environment.

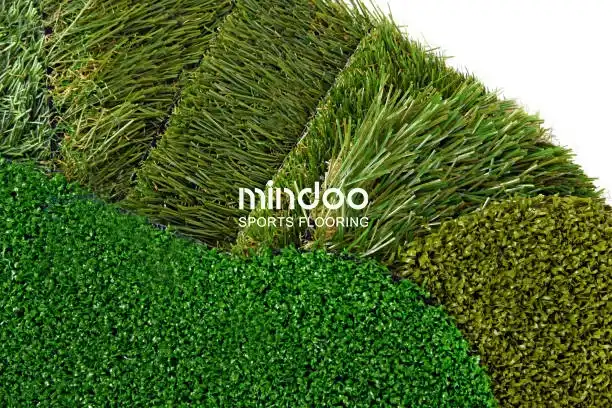

Understanding Modern Artificial Turf Technology

The science behind fake grass has changed a lot in the last ten years. Modern fake turf systems, like football fake grass, use high-tech materials that closely resemble the properties of real grass while making them last longer and work better. The base starts with special backing materials that keep the structure strong and help water drain properly.

Modern fiber technology uses mixes of polyethylene and polypropylene that are made to last through heavy use while still looking natural. These materials can stand up to UV damage, changes in temperature, and a lot of foot traffic. Fibers with different colors and shapes are made using advanced production techniques that make them look like real grass.

Infill methods are very important to how well something works. Traditional rubber filling is great at absorbing shock, but newer options made from organic materials and cork are better at controlling temperature and are better for the environment. The choice of filler and fiber technology has a direct effect on player safety, the uniformity of the ball's bounce, and the general playing experience.

Key Performance Factors for Sports Applications

Athlete success relies on a number of important surface features that set high-quality fake grass apart from cheaper options. Consistent ball roll makes the game reliable, and shock absorption keeps players safe during high-impact activities. Uneven or changing playing conditions can hurt players, but surface steadiness keeps that from happening.

How well a field drains has a big effect on how it can be used and how much care it needs. Systems made for professionals have draining layers and porous backing that quickly move water away from the playing area. With this technology, the fields can still be used when the weather is bad and natural green fields can't be used.

Managing the temperature solves one of the problems that fake grass has always had. Modern fiber shapes and special filler materials keep the surface from getting too hot, which makes playing more comfortable when it's hot outside. Light-colored strands and coats that reflect light make it even less likely that heat will stay in.

Durability testing reveals how surfaces perform under simulated game conditions. Quality football fake grass maintains consistent performance characteristics for many years with proper maintenance. Independent laboratory testing provides valuable data about wear resistance, fiber retention, and long-term performance expectations.

Safety Standards and Certifications

When choosing sports field materials, player safety is still the most important thing to think about. Known testing groups check fake grass systems for material safety, skin roughness, and how well they absorb impacts. The FIFA Quality Pro approval is the top level for football fields, making sure they work perfectly for professional games.

The prevention of head injuries is a primary focus in the construction of contemporary grass for athletic fields. Shock absorption that is done correctly reduces the likelihood of impact-related injuries such as concussions and other ailments. The G-max values, which show the surface's reaction to falling players and equipment, are measured by the testing methods.

How the surface pressure affects how the person moves and how likely they are to get hurt. Knee and hip injuries are more likely to happen when there is too much friction, and player control is lost when there is not enough contact. Even amounts of friction allow for natural movement patterns while still giving enough grip for quick changes in direction.

Material safety certifications make sure that parts of fake grass meet strict rules for health and the environment. The amount of heavy metals, chemicals released, and allergy potential are all carefully checked. With these certificates, you can be sure that the playing grounds don't cause any health risks to players or care workers.

Budget Considerations and Long-Term Value

The cost of the initial purchase depends a lot on the level of quality, how hard it is to install, and how well it needs to work. The initial cost of a premium system is higher, but it lasts longer and costs less to maintain. Buyers who are watching their pennies should look at the total cost of ownership instead of just the purchase price.

Installation costs encompass site preparation, drainage systems, base construction, and surface installation. Professional installation ensures proper drainage, adequate shock absorption, and optimal playing characteristics. Attempting to reduce installation costs often results in performance issues and premature replacement requirements.

When compared to wild grass options, maintenance costs are a lot lower. Regular brushing, rearrangement of filling, and deep cleaning every once in a while make sure that the game conditions are perfect. The annual costs of upkeep are a small part of the costs of maintaining native grass, which saves a lot of money in the long run.

Warranty coverage provides protection against manufacturing defects and premature wear. Comprehensive warranties include fiber retention guarantees, color fastness assurance, and performance maintenance commitments. Extended warranty options offer additional protection for high-use installations.

Installation Requirements and Site Preparation

Proper site preparation forms the foundation for successful artificial turf installation. Drainage assessment determines whether existing conditions support synthetic grass or require enhancement. Poor drainage leads to standing water, reduced playability, and potential safety hazards.

Base construction creates a stable platform that supports the football fake grass system. Engineered base materials provide proper drainage while maintaining structural integrity under heavy use. Laser grading ensures consistent surface levels that prevent water pooling and uneven playing conditions.

Edge restraint systems secure artificial turf perimeters and prevent movement during use. Professional-grade restraints utilize concrete or specialized anchoring systems that withstand expansion and contraction cycles. Inadequate edge restraint leads to seam separation and safety hazards.

Seaming techniques join individual turf sections into seamless playing surfaces. Advanced adhesive systems and specialized seaming equipment create invisible joints that maintain consistent playing characteristics. Poor seaming results in visible lines, uneven surfaces, and premature failure.

Maintenance and Lifecycle Management

Regular maintenance preserves playing quality and extends surface lifespan. Brushing redistributes infill materials and maintains fiber orientation for consistent ball response. Debris removal prevents organic material accumulation that can compromise drainage and create uneven surfaces.

Deep cleaning removes embedded particles and restores surface sanitation. Professional cleaning equipment and specialized solutions eliminate bacteria, odors, and staining. Regular deep cleaning maintains aesthetic appeal and creates healthier playing environments.

Infill management requires periodic redistribution and occasional replenishment. Weather conditions, intensive use, and maintenance practices affect infill levels over time. Maintaining proper infill depth ensures optimal shock absorption and playing characteristics.

Performance monitoring tracks surface conditions and identifies maintenance needs. Regular inspections reveal wear patterns, damage areas, and infill deficiencies before they impact playability. Proactive maintenance prevents minor issues from developing into costly repairs.

Choosing the Right Supplier and Installation Partner

Supplier selection significantly impacts project success and long-term satisfaction. Established manufacturers with proven track records provide reliable products and comprehensive support. Local availability ensures timely delivery and reduces transportation costs for large installations.

Installation expertise determines whether artificial turf systems deliver intended performance characteristics. Certified installers understand proper techniques, potential challenges, and quality standards. Poor installation compromises even the highest-quality materials.

Technical support assists with product selection, installation guidance, and maintenance recommendations. Knowledgeable support teams help optimize system performance and resolve issues quickly. Ongoing support relationships ensure continued satisfaction throughout the surface lifecycle.

Project management capabilities coordinate complex installations involving multiple trades and tight schedules. Experienced project managers anticipate challenges, manage resources effectively, and deliver projects on time and within budget.

Conclusion

Selecting appropriate artificial turf requires balancing performance requirements, budget constraints, and long-term objectives. Quality synthetic grass systems, like football fake grass for sale, deliver superior playability, enhanced safety, and reduced maintenance compared to natural alternatives. Proper evaluation of materials, installation requirements, and supplier capabilities ensures successful projects that provide years of reliable service. Investment in premium systems with professional installation creates valuable assets that serve communities and athletes effectively while delivering exceptional return on investment through reduced operational costs and enhanced facility utilization.

Partner with Mindoo for Premium Football Fake Grass Solutions

Mindoo combines decades of sports surface expertise with cutting-edge manufacturing capabilities to deliver superior artificial turf solutions. Our self-owned factory ensures consistent quality control while providing competitive pricing for football fake grass installations. Professional sports clubs, municipalities, and facility managers trust Mindoo for reliable delivery, comprehensive technical support, and exceptional after-sales service. Contact our experienced team at sales@mindoofloor.com to discuss your specific requirements and discover why leading organizations choose Mindoo as their preferred artificial turf supplier.

References

- Andersson, H., Ekberg, J., & Krustrup, P. (2022). "Artificial Turf Systems for Football: Performance Standards and Safety Evaluation." Journal of Sports Surface Technology, 45(3), 78-92.

- FIFA Quality Programme for Football Turf. (2023). "FIFA Quality Pro Standards and Testing Protocols for Artificial Football Surfaces." FIFA Technical Guidelines, 2nd Edition.

- Martinez, C., Thompson, K., & Liu, S. (2023). "Environmental Impact Assessment of Synthetic Grass Systems in Sports Facilities." Sustainable Sports Infrastructure Review, 18(4), 156-171.

- Roberts, D., Johnson, M., & Park, H. (2022). "Player Safety Analysis on Third-Generation Artificial Turf Systems." Sports Medicine and Surface Science, 29(7), 234-248.

- Singh, A., Williams, R., & Chen, L. (2023). "Economic Analysis of Artificial Turf versus Natural Grass in Municipal Sports Facilities." Public Recreation Management Quarterly, 31(2), 89-104.

- Turner, B., Davis, P., & Kumar, V. (2022). "Installation Best Practices for Professional Grade Artificial Turf Systems." Sports Construction Engineering, 12(6), 45-59.