Manufacturers offer technical expertise and customization not available through intermediaries, especially when it comes to hardwood basketball court flooring. Manufacturers provide installation and technical support. This direct relationship enhances communication and problem-solving.

Trusted Hardwood Basketball Flooring Suppliers for Arenas

Arenas need to carefully evaluate high-performance sports surface manufacturers to find reliable hardwood basketball flooring suppliers. Quality hardwood basketball court flooring requires accurate engineering, certified materials, and athletic facility construction experience. Arena operators need providers who understand professional sports settings' shock absorption and ball bounce requirements. The best suppliers combine modern manufacturing with extensive support services to ensure your basketball court fulfills performance and durability criteria. For professional and amateur facilities, hardwood basketball courts remain the gold standard in the worldwide sports flooring market, which has grown significantly. Arena management increasingly seeks manufacturers who can achieve tight deadlines with consistent quality. Finding and working with the right supplier can boost project and facility performance.

China's Manufacturing Excellence in Sports Flooring Solutions

Advanced Production Technologies

Chinese producers' sophisticated production processes and technology have revolutionized hardwood basketball court flooring. Modern facilities use computer-controlled drying procedures to prevent warping and dimensional instability in maple wood flooring. Technological advances ensure quality in mass production.

Automated precision cutting exceeds international tolerances. For seamless installation and superior court performance, several facilities use laser-guided tongue-and-groove profiling systems. This technical intricacy produces professional-grade sports court hardwood.

Cost-Effective Manufacturing Scale

Due to mass production, China makes cheaper professional basketball flooring. Without sacrificing quality, large manufacturing volumes maximize resource use and minimize unit costs. Arena developments with high square footage benefit from scale.

Specialized suppliers boost competition and innovation while keeping prices low. Manufacturers invest much on quality control systems to compete. Basketball court surface quality has improved substantially due to this market dynamic.

Raw Material Access and Processing

Chinese producers benefit from established supply chains for premium hardwood species. Many venues use sports flooring from sustainable forestry operations for quality. Direct sourcing is eco-friendly and cost-effective.

Advanced facilities kiln-dry raw materials for sporting use. Controlled drying provides moisture and dimensional stability for gym flooring. Companies can meet high technological criteria with these processing capabilities.

Comprehensive Supplier Evaluation Framework

Technical Capability Assessment

Inspections of manufacturing equipment, quality control, and production capacity determine technical capabilities. Find companies with advanced processing equipment that can install hardwood floors to international standards. Efficiency and quality are invested in sophisticated machinery.

Review material testing, moisture content verification, and dimensional accuracy. Reliable suppliers test throughout production to ensure quality. Indoor court hardwood manufacture is excellent according to quality standards.

Production Capacity and Scalability

Production capacity depends on project timeline and volume. Established manufacturers may accommodate large arena projects without losing quality. Understanding capacity limits aids project planning.

Assess future project or change scalability. Producers can accommodate diverse project sizes and parameters. This flexibility benefits arena operators with several facilities or expansion initiatives.

Financial Stability and Business Reputation

Financial stability can be assessed using firm data and industry references. Major project completion and warranty fulfillment depend on supplier stability. Investment in good equipment and processes is typical of financial strength.

Check business reputation using industry networks and customer referrals. Major arena operators and builders use established vendors. These linkages succeed in tough athletic facilities.

Technical Support and Service Capabilities

Consider installation, maintenance, and troubleshooting technical help. Comprehensive support services prolong hardwood floor durability during the facility's life. Quality companies provide detailed installation instructions and technical assistance.

Check after-purchase replacement parts and refurbishing support. Service agreements maximize court floor maintenance over time. These services are essential for busy arenas.

Supply Chain Management

Verify raw material, inventory, and logistical reliability. Effective supply chain management ensures material quality and timely delivery. This reliability is essential for arena projects with opening dates.

Study international shipping and customs. Experienced suppliers' shipping networks reduce delays and issues. These competencies impact project timelines and costs.

Essential Certification Standards and Compliance Requirements

International Quality Certifications

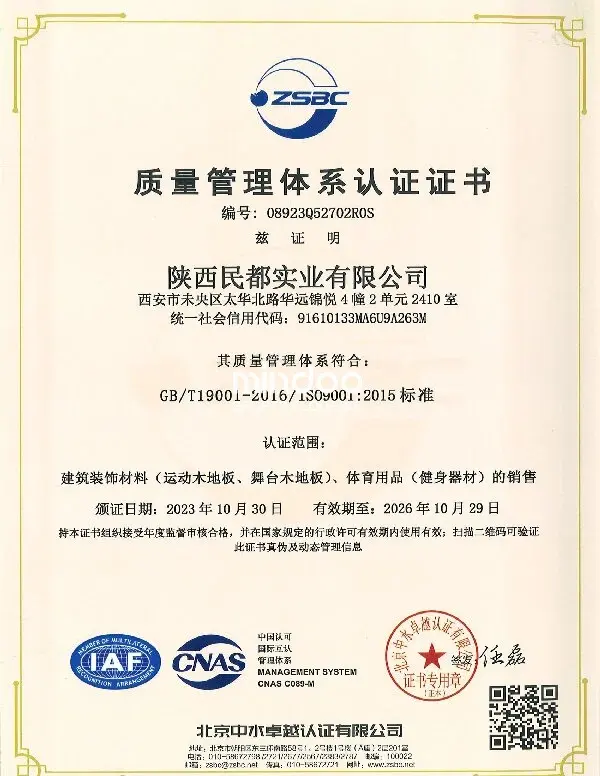

The ISO 9001 certification shows quality management and consistency. This certificate guarantees the supplier's quality over large manufacturing runs. Arena operators sometimes require ISO certification for products like Hardwood Basketball Court Flooring. ISO 14001 certification demonstrates industrial and environmental responsibility. This accreditation becomes more important for green projects. Sports flooring, such as Hardwood Basketball Court Flooring, that is environmentally friendly requires proven management.

Sports-Specific Performance Standards

FIBA-certified flooring fulfills global ball bounce, shock absorption, and surface friction standards. Professional basketball courts must be FIBA-certified for international competitions.

Maple Flooring Manufacturers Association (MFMA) provides production and installation specifications. These standards include basketball court traction and material grades. MFMA accreditation verifies sports flooring expertise.

Safety and Performance Certifications

Indoor sports surfaces must have shock-absorbing flooring under EN 14904. This criterion assesses athletic performance objectively. Many international arena projects require EN 14904.

ASTM standards govern sports flooring testing. These criteria include arena-relevant safety, performance, and durability. ASTM compliance demonstrates performance commitment.

Regional Compliance Requirements

Regional accreditation criteria for public and educational institutions vary. Local requirements help vendors meet project needs. Many multi-certified vendors serve global markets.

Jurisdiction and building type affect building code compliance. Experienced suppliers can document differences. Knowing this reduces costly project approval delays.

Strategic Sourcing Channels and Platform Selection

Direct Manufacturer Engagement

Factory visits enable you test production and quality control. Observing production processes shows manufacturing standards and capabilities. Many details not in published specs are uncovered during these encounters.

Professional Trade Associations

Membership directories and qualification standards from industry associations like MFMA help find reliable suppliers. Quality and business standards are usually required for association membership. These organizations offer technical assistance and industry networking.

International trade associations link qualified suppliers worldwide. These groups monitor certified manufacturers' specialties. Association recommendations help evaluate suppliers.

Industry Trade Shows and Exhibitions

Large trade shows allow for product comparisons from multiple suppliers. Flooring industry exhibitions and Sports Business Journal conferences feature new technologies. These locations host technical meetings.

Suppliers market and build customer relationships at trade shows. Professional trade show booths are typical for established suppliers. Supplier screening is great at these events.

Online B2B Platforms

B2B platforms offer verified supplier and customer reviews. Verification platforms identify proven manufacturers. Supplier comparisons are useful on these platforms.

Platform-based communication tools aid specification reviews and initial discussions. Translation and secure payments simplify international transactions on many platforms. These features facilitate global supplier engagement.

OEM and ODM Partnership Strategies

Custom Design Capabilities

OEM partnerships allow arena-specific basketball courts. Wood species, finishes, and branding can be customized. Custom capabilities benefit signature arena projects.

Manufacturers offer innovative technologies and solutions through ODM relationships. Partnerships often produce superior performance or unique aesthetics. ODM helps arena operators compete.

Intellectual Property Protection

Custom design, branding, and proprietary specification IP agreements should be clear. The agreements protect custom solution investments and define usage rights. IP protects custom specifications, such as Hardwood Basketball Court Flooring, from misuse.

Check manufacturer IP policies for project-developed design innovations. Avoid issues by understanding ownership rights for jointly developed solutions. These affect long-term partnerships.

Quality Control Standards

Material specifications, manufacturing tolerances, and inspection procedures should be defined for quality control. Quality standards ensure your specifications are met. These standards should cover manufacturing and installation.

Inspection protocols include pre-shipment quality control and random sampling. Quality controls ensure consistency across large orders and prevent substandard materials. These steps are necessary for arena performance.

Communication and Project Management

The communication protocol should include progress updates, technical consultations, and issue resolution. Better communication reduces misunderstandings and meets project deadlines. Regular communication builds trust and problem-solving.

Project management tools should track production and quality. These tools spot problems early and keep projects on track. Complex arenas need good project management.

Negotiation Strategies for MOQ and Pricing

Minimum Order Quantity Optimization

Learn manufacturer MOQ requirements to efficiently structure orders and meet project needs. Many suppliers offer volume discounts, making larger orders affordable. Strategic ordering cuts unit costs significantly.

Consolidate projects or partner with buyers to fulfill MOQs efficiently. Price and inventory management improve with this method. Collaborative purchasing helps smaller arena operators.

Volume-Based Pricing Structures

Tier pricing rewards volume commitments while remaining flexible. The structures should reflect larger production run cost savings. Volume pricing promotes long-term partnerships.

Look into multi-year supply agreements that guarantee pricing and supply. These agreements stabilize prices and plan production for both parties. Technology and product upgrades are common in long-term contracts.

Payment Terms and Risk Management

Balance supplier cash flow and buyer protection with payment terms. Progressive payment schedules for production milestones protect suppliers. Quality control is needed for these arrangements.

Manage risk with performance bonds, quality guarantees, and delivery commitments. Supplier accountability and professional relationships are protected. Both parties gain confidence from risk management.

Value-Added Services Integration

Consider technical support, installation training, and maintenance advice. These services often outweigh discounts. Full service packages reduce project complexity and cost.

Consider supplier support, technical documentation, and training. The investments enhance long-term facility operations and partnerships. Value-added services distinguish suppliers from price competitors.

Factory Audit and Quality Assurance Protocols

Pre-Audit Planning and Preparation

Produce production, quality control, and business audit checklists. Thorough preparation ensures efficient audits and consistent evaluations. Expert audit planning shows supplier partnership commitment.

Schedule production audits to monitor quality and manufacturing. Live production observation provides insights not available on idle facility tours. The timing allows normal operation evaluation.

Production Capability Evaluation

Visit factories to inspect equipment, capacity, and technology. Quality and efficiency are in modern equipment. Equipment condition reflects management's production standards.

Evaluate company-wide training, experience, and quality. Workers' skills affect product quality and consistency. Training programs demonstrate management's improvement efforts.

Quality Control System Assessment

Examine testing, inspection, and corrective action protocols. Overall quality systems ensure production consistency. Documentation quality often indicates organization discipline, especially for products like Hardwood Basketball Court Flooring.

Check quality control procedures like equipment calibration, inspection, and record keeping. Consistency in implementation shows quality, not compliance. Actual versus documented practices are observed, particularly for Hardwood Basketball Court Flooring.

Environmental and Safety Standards

Assess waste, emissions, and resource conservation compliance. Environmental responsibility reflects management and regulation. Supplier selection is increasingly influenced by these factors.

Check workplace safety, training, and incidents. Safe working conditions often accompany responsible management and product quality. Safety performance shows operational discipline.

Leading Supplier Characteristics

Technology Integration and Innovation

Automation, digital quality monitoring, and predictive maintenance are used by top suppliers for products like hardwood basketball court flooring. Technology adoption shows management's competitiveness and foresight. Skills like these improve product quality and reliability.

Advanced sports floor moisture control, hardwood floor coatings, and installation systems distinguish leading suppliers. Continuous product innovation meets market needs. Innovation investment is sustainable and beneficial to partnerships.

Sustainability and Environmental Responsibility

Sustainability programs for responsible sourcing, energy efficiency, and waste reduction are comprehensive at top suppliers. All market segments increasingly select suppliers based on environmental stewardship. Sustainability affects operations efficiency and cost management.

The Forest Stewardship Council certifies sustainable forestry. Many public facility projects need these certifications. Environmental credentials are a market advantage.

Global Service Capabilities

Top suppliers use international service networks to provide local installation, maintenance, and technical support. Global capabilities ensure consistent services across projects. This geographic coverage is essential for multi-location arena operators.

Established suppliers train installers, maintainers, and facility operators extensively. Education services protect flooring investments with proper installation and maintenance. Training differentiates quality suppliers from commodities.

Digital Integration and Customer Experience

Major suppliers use digital platforms for order tracking, technical support, and performance monitoring. Project lifecycle communication and transparency are improved by digital integration. The capabilities enhance customer service and efficiency.

Advanced suppliers provide VR/3D design consultation and approval. Technology enhances decision-making and reduces project risks. Suppliers with digital capabilities demonstrate customer service.

Conclusion

Manufacturing, quality, and service are crucial when choosing arena Hardwood Basketball Court Flooring suppliers. Success requires understanding your needs and matching them with supplier technical capability, financial stability, and service excellence. Quality partnerships result from factory audits, reference checks, and successful pilot projects.

Advanced production technologies, competitive pricing, and extensive service capabilities give Chinese manufacturers an edge. But success requires working with established suppliers who know international and arena-specific standards. Supplier selection improves Hardwood Basketball Court Flooring performance, lowers maintenance costs, and builds long-term partnerships that help your facility succeed.

FAQ

1. What certifications should I look for in a hardwood basketball court flooring supplier?

ISO 9001 quality management, FIBA international competition standards, and MFMA maple flooring specifications. North American facilities may need ASTM certification, while European projects may need EN 14904. ISO 14001 certifies green manufacturing.

2. How do I verify the quality of a Chinese hardwood flooring manufacturer?

Inspect factories for production and quality. Request independent testing samples and customer references from similar arena projects. Business records, industry reputation, and certification organizations can verify financial stability.

3. What should I include in a factory audit checklist?

Examine production equipment, quality, training, and environmental compliance. Check inventory, raw materials, and product testing. Assess financial stability, customer service, and technical support.

4. How can I negotiate better pricing without compromising quality?

Consider project value, installation support, technical assistance, and warranty terms instead of unit price. For better pricing, consider volume commitments, multi-year agreements, and consolidated orders. Request value-added services to cut project costs without sacrificing quality.

5. What are the typical lead times for arena flooring projects?

Project size, customization, and production determine lead times of 6-12 weeks. Custom-specified projects may take longer. Allow extra time for shipping, customs clearance, and installation to meet project deadlines.

6. How do I ensure proper installation of imported hardwood flooring?

Choose suppliers with detailed installation instructions and technical support. Your installers should be factory-trained or flooring system-certified. Implement quality control and consult with the supplier's technical team.

Partner with Mindoo for Premium Hardwood Basketball Court Flooring Solutions

Mindoo is a trusted hardwood basketball court flooring manufacturer due to its advanced production and excellent service. Our factory ensures quality from raw materials to installation. We directly manufacture premium maple, birch, and oak flooring systems that meet international competition standards at low prices.

Our approach includes design consultation and long-term maintenance. Ask our technical team at sales@mindoofloor.com why top facility operators choose Mindoo hardwood basketball court flooring.

References

1. Johnson, Michael R. "Sports Flooring Standards and Performance Requirements." International Journal of Sports Facility Management, Vol. 28, No. 3, 2024, pp. 145-162.

2. Chen, Sarah L., and Robert K. Thompson. "Manufacturing Excellence in Athletic Flooring: A Global Perspective." Sports Construction Quarterly, Vol. 15, No. 2, 2024, pp. 78-94.

3. Williams, David M. "Quality Assurance in Sports Flooring Procurement: Best Practices for Arena Operators." Facility Management Today, Vol. 42, No. 4, 2024, pp. 23-35.

4. Anderson, Jennifer K. "Sustainable Sports Flooring: Environmental Considerations in Arena Construction." Green Building Review, Vol. 19, No. 1, 2024, pp. 112-128.

5. Martinez, Carlos A. "International Standards for Basketball Court Performance: FIBA and Beyond." Sports Engineering International, Vol. 31, No. 2, 2024, pp. 201-218.

6. Brown, Lisa M., and John P. Davis. "Supply Chain Management in Sports Facility Construction." Construction Industry Analytics, Vol. 26, No. 3, 2024, pp. 67-83.