Finding the proper Chinese wood basketball floor manufacturer takes careful consideration of quality, certifications, and manufacturing. China's sports flooring sector has grown to produce excellent hardwood flooring that meets international athletic surface specifications. Shock absorption, durability, and precision ball bounce are essential for professional basketball courts. Mindoo and other top sports flooring manufacturers use innovative manufacturing techniques, raw material procurement, and quality assurance systems to supply superior products to worldwide markets.

China's Manufacturing Excellence in Hardwood Sports Flooring

China leads the world in sports flooring manufacture with superior technology and excellent workmanship. The country's industrial environment benefits professional basketball floor manufacture.

Superior Production Infrastructure

Chinese firms have substantially invested in modern manufacturing facilities. Wood processing in modern companies uses precise technology to ensure dimensional correctness and surface quality. These facilities house wood selection, finishing, and other manufacturing steps.

Temperature-controlled surroundings optimize wood processing and curing. In varied regions, automated systems check moisture content throughout manufacture to ensure dimensional stability. Quality control labs rigorously test performance criteria.

Excellent Raw Material Sources

Access to premium hardwood species provides Chinese producers an advantage. Maple wood, the best for basketball courts, comes from sustainable forests with rigorous quality standards. Oak, birch, and beech are lower-cost alternatives without sacrificing performance.

Vertical integration lets producers manage the supply chain. Direct wood supplier connections guarantee quality and low prices. This integration removes middleman markups, improving consumer value.

Tech Innovation and Expertise

Chinese businesses use cutting-edge technologies to improve quality. For flawless tongue-and-groove installations, computer-controlled machining assures precision. UV-cured finishes are scratch-resistant and durable.

Performance is the emphasis of R&D. Advanced subfloors absorb stress and return energy. Moisture-resistant treatments withstand environmental obstacles in different climates.

Essential Criteria for Selecting Reliable Basketball Floor Manufacturers

Selecting a manufacturer needs careful consideration of several criteria. These criteria identify partners that provide excellent sporting surfaces.

Scalability and production capacity

Make sure the manufacturer can manage your job. Large sports complexes need much of flooring quickly. Evaluate monthly output and urgent project prioritization.

Review prior project portfolios for comparable installation experience. Professional arenas, school gymnasiums, and training facilities face distinct issues. Experienced manufacturers adapt and solve problems.

Compliance with Technical Specifications

Professional basketball courts have performance requirements. Check that manufacturers meet shock absorption, ball bounce, and surface friction standards. Minimum 53% shock absorption and 90% ball rebound are required.

Demand technical proof for all performance claims. Product capabilities are verified by independent lab testing. Test according to FIBA or BWF norms.

QMSs

Product performance is ensured by strong quality control. Manufacturers should employ thorough inspection methods throughout manufacturing. Record testing frequencies, review methods, and remedial actions.

ISO 9001 certifies systematic quality management. Additional manufacturing certificates show excellence. Regular third-party audits verify standards compliance.

Customer Support Skills

Successful project completion requires responsive customer service. Assess technical support, response times, and communication channels. Throughout the project, multilingual workers communicate clearly.

Flooring purchases, such as wood basketball floor systems, benefit from installation help. Local teams may get installation supervision or training from certain manufacturers. Post-installation assistance addresses warranty and maintenance concerns.

Supply Chain Dependability

Construction project coordination requires reliable delivery timetables. Check manufacturer logistics and shipping relationships. Flexible delivery choices meet project needs and budgets.

Inventory management methods assure material availability. Maintaining stock lets manufacturers react swiftly to urgent needs. Critical materials are protected by backup suppliers.

Customization and Design Flexibility

Project needs frequently necessitate specialized solutions. Assess manufacturer willingness and capacity to change typical items. Custom dimensions, finishes, and performance may be needed for certain installations.

Design assistance optimises flooring systems for specific applications. Prevent expensive changes with technical talks throughout planning. Collaboration improves results for everybody.

Critical Certifications and Standards for Athletic Flooring

International certifications verify product quality and performance. Manufacturer competence and product dependability are assured by these certifications.

Sports Federation Approvals

FIBA accreditation verifies basketball standards compliance. Official competition sites must have this permission, and training facilities should too. BWF accreditation meets badminton-specific multi-sport facility standards.

These certifications involve extensive surface testing. Shock absorption, friction, and ball bounce must be precise. Recertification guarantees conformity with changing requirements.

International Quality Standards

The ISO 14001 environmental certification shows sustainable production. Environmentally concerned initiatives need this standard more. GREENGUARD certifies minimal emissions for indoor air quality.

CE certification verifies European safety requirements. International commerce and quality assurance are aided by this accreditation. RoHS compliance verifies hazardous substance-free production.

Regional Building Code Compliance

Sports facilities may have extra building code requirements. Fire, slip, and accessibility ratings differ per jurisdiction. Experienced producers may comply with these standards.

Certificates and test results should be included in documentation packages. Complete paperwork speeds up approvals and saves project delays. Manufacturers should monitor shifting rules.

Effective Sourcing Strategies and Platform Selection

Qualified manufacturers are accessible via many routes. Each method has benefits based on project needs and procurement preferences.

Manufacturer Direct Engagement

Products and services are usually better when purchased directly from makers. This method avoids distributor markups and ensures decision-maker communication. Manufacturers provide technical support and customization, especially for specialized products like wood basketball floor systems.

Trade exhibitions are a great opportunity to meet manufacturer reps. Domotex and China International Flooring Expo offer new products and enable comparisons. Follow-up plant inspections reveal capabilities and procedures.

B2B Platform Use

Online platforms help find and compare suppliers. Complete supplier profiles contain product catalogs, certificates, and customer reviews. Advanced search filters restrict results by need.

Platform verification systems boost international transaction security. Trade assurance prevents shortages and quality difficulties. Secure payments enable secure financial transactions.

Industry Network Links

Professional groups and industry networks provide good references. Experiences with particular manufacturers by colleagues provide useful knowledge beyond marketing. Sports facility managers typically have favored suppliers.

Given their independence, consultant suggestions are important. Flooring experts know technical requirements and propose manufacturers. Their partnerships provide competitive prices and priority service.

Strategic Approaches to OEM and ODM Partnerships

Original Equipment Manufacturing and Original Design Manufacturing benefit big or specialized projects. To succeed, these collaborations must be carefully structured.

OEM Partnership Benefits

OEM agreements enable your organization to brand manufacturer items. This strategy helps distributors and contractors create brand awareness. Private labeling differentiates products in competitive marketplaces.

Volume agreements may provide better price and production schedule. Long-term contracts reduce procurement costs and secure supplies. Large volume commitments may provide exclusive geographical rights.

Opportunities for ODM Collaboration

ODM collaborations allow speciality product creation for particular markets. This method works when regular items don't fulfill criteria. Custom solutions are more affordable with shared development expenses.

Intellectual property agreements must be carefully negotiated to safeguard all parties. Clear design, manufacturing, and market areas agreements avoid disagreements. Collaborative development uses knowledge to improve outcomes.

Partnership Structure Considerations

OEM/ODM order minimums surpass conventional buying thresholds. Check your market ability to meet volume obligations. Implementation in phases may reduce risk and increase market demand.

Partnership agreements must provide quality control. Document inspection techniques, acceptance criteria, and remedial actions. Regular review sessions handle new concerns and maintain alignment.

Effective Negotiation Tactics for MOQ and Pricing

Manufacturer cost structures and market dynamics are essential for successful negotiations. Strategic methods may improve terms and connections.

Minimum Order Quantity Optimization

Manufacturers set MOQs for efficiency and profit. Understanding economics helps find bargaining possibilities. Multiple product specifications in one purchase, such as different wood basketball floor components, may lower MOQs.

Flexible scheduling may benefit both parties. Manufacturers may accept split deliveries to ease inventory management and production efficiency. Advance ordering during sluggish times may improve price.

Pricing by Volume

Annual volume agreements typically provide considerable reductions over spot purchasing. Predict future needs to maximize bulk price. Price protection features in multi-year agreements may save more.

Market time greatly impacts price discussions. Better price is usually available during off-peak ordering. Understanding factory capacity usage helps determine negotiating time.

Finance and Payment Terms

Payment terms affect project costs via finance. Extended payment periods may justify higher unit costs. Financially flexible purchasers get instant cost savings with early payment incentives.

International letters of credit protect both parties. Trade financing helps manage cash flow and get good prices. Some manufacturers give qualifying consumers loans.

Comprehensive Factory Evaluation and Quality Assurance

Factory inspections reveal manufacturing capability and dependability. Systematic assessment helps uncover project flaws before they happen.

Production Facility Assessment

Factory tours show manufacturing capability. Quality and efficiency are invested in modern equipment. Maintenance standards show management's operational focus. Cleaning and organization reflect methodical manufacture.

Quality control labs test and verify. Instrument calibration ensures precise measurements and outcomes. Frequent testing and documentation show quality management maturity.

Managing System Evaluation

Delivery reliability and product quality depend on management expertise. Interview key persons to evaluate technical and problem-solving skills. Project coordination is easier with English proficiency.

Document management systems show organizational maturity and dependability. Good record-keeping aids warranty claims and quality investigations. Traceability systems easily find and fix quality concerns.

Environmental and Safety Standards

Environmental compliance shows industrial responsibility. Waste management methods show sustainability and regulation. Management ideals and operational discipline show in worker safety initiatives.

Continuous investment is needed to maintain certification. Ongoing audits demonstrate dedication to progress. Corrective action tracking solves problems methodically.

Identifying Premier Wood Basketball Floor Suppliers

New technology and performance standards are changing sports flooring. Leading manufacturers thrive in innovation, quality, and service.

Tech Leadership and Innovation

Research and development are ongoing for advanced manufacturers. New finishing methods increase durability and maintenance. Improved sub-floor systems improve player safety and performance, especially in specialized products like wood basketball floor systems.

Digital integration simplifies ordering and project management. Customers imagine personalized designs via online configurators. Project tracking systems update production and delivery status live.

Environmental Responsibility and Sustainability

Sustainable sourcing becomes more crucial for eco-conscious shoppers. FSC certifies responsible forest management. Environmental commitment is shown via carbon footprint reduction projects.

Eco-friendly finishes enhance indoor air quality without losing performance. Green building approved low-VOC formulas. End-of-life product recycling promotes circular economy.

Service capabilities worldwide

International producers help local markets via regional offices or partners. Floor installation training ensures correct installation. Maintenance training prolongs floor life and warranties.

Comprehensive warranties show manufacturer confidence in product quality. Extended warranties give value and comfort of mind. Customer loyalty is maintained with responsive warranty service.

Conclusion

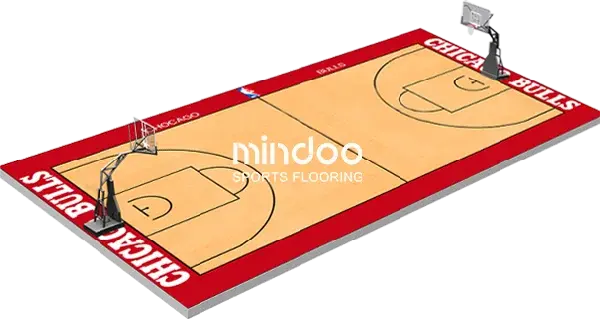

Production, quality, and service support must be considered while choosing a Chinese wood basketball floor manufacturer. Chinese manufacturing provides great value due to sophisticated technology, reasonable cost, and extensive service. Thorough supplier assessment, clear expectations, and methodical quality assurance methods are key to successful relationships. Professional sports facilities need durable, high-performance flooring. Leading manufacturers like Mindoo show the industry's improvement in quality and service. Their integrated manufacturing, quality control, and customer support redefine sports flooring.

Proper supplier selection improves product quality, cost, and project delivery. Use the following criteria to carefully assess prospective partners.

Frequently Asked Questions

Q1: What certifications should a wood basketball floor manufacturer have?

A: Sports performance certificates like FIBA or BWF, quality management certifications like ISO 9001, and safety certifications like CE marking are essential. FSC and GREENGUARD certifications suggest eco-friendly items. These certificates prove producers satisfy global quality, performance, and safety requirements.

Q2: How can I check Chinese manufacturer quality before ordering?

A: Audit factories' production and quality control systems. Request samples for independent performance testing and verification. Consult customer references and project portfolios. Third-party inspections may evaluate manufacturing quality objectively.

Q3: What is the average bespoke wood basketball floor lead time?

A: Standard goods take 3-4 weeks to make and ship. Complex specs might increase lead times to 6-8 weeks. Large items or special requests take 8-12 weeks. Early planning and strong communication help meet construction timetables.

Q4: How do I install imported basketball flooring properly?

A: Use manufacturers with extensive installation instructions and technical assistance. Suppliers may provide on-site monitoring or installation training. Expert sports flooring contractors using worldwide goods. Installations need proper acclimatization and environmental controls.

Partner with Mindoo for Premium Wood Basketball Floor Solutions

Mindoo is a recognized wood basketball floor manufacturer with modern manufacturing facilities and excellent customer service. Quality control is maintained from premium hardwood selection to finishing in our own plant. Mindoo produces high-performance sports surfaces with FIBA accreditation and worldwide project expertise. You may trust us for your next basketball court project because to our cheap price, customization options, and skilled installation. Contact us at sales@mindoofloor.com to discuss your specific requirements and receive a detailed quotation.

References

1. International Basketball Federation (FIBA). "Technical Requirements for Basketball Facilities." FIBA Equipment and Venue Manual, 2023 Edition.

2. Zhang, L., & Chen, M. "Evolution of Sports Flooring Manufacturing in China: Quality Improvements and International Competitiveness." Journal of Sports Facility Management, Vol. 45, 2024.

3. Sports Flooring International Association. "Global Standards for Athletic Surface Performance and Safety." Annual Technical Report, 2024.

4. Thompson, R. "Sustainable Practices in Hardwood Sports Flooring Production." Wood Technology and Manufacturing Review, Issue 3, 2024.

5. Athletic Facility Management Association. "Best Practices for Sports Flooring Procurement and Installation." Professional Guidelines Handbook, 2024.

6. Chen, W., & Liu, X. "Quality Assurance in Chinese Manufacturing: A Case Study of Sports Flooring Industry." International Journal of Quality Management, Vol. 28, No. 4, 2024.